ABOUT

Locally farmed fish that’s drawing in the world.

“We’ve worked really hard to rear a barramundi like no other in Singapore and we hope you can enjoy this healthy and delicious fish with your family, friends and loved ones.”

Joep Staarman

Founder

Scroll to start journey

01

Nursery: Hello, Singapore!

Pulau Semakau is where our non-GMO fry, each weighing about 0.1-0.2gm, set up home upon arrival from Australia. With delicate nursing, they grow into fingerlings.

At this stage, our baby fish are individually vaccinated with SFA-approved vaccines to protect them against diseases. Made up of only protein – it’s all good for the fish, the environment and you.

Loic Monteil,

Nursery Manager

“Our baby fish are individually vaccinated by hand with a huge dose of tender loving care to ensure that each one is effectively protected against both viral and bacterial diseases.”

Every day, we run tests on water quality to ensure a safe and ideal environment for our baby fish.

Marie Tan,

Assistant Fish Health Manager

“Our well-equipped on-site lab is where I run various tests on the samples collected from our fish daily, to make sure they are free from bugs and in tip-top condition!”

Scroll to Continue

02

Open-Sea Farm: Our new home

Scroll to Continue

03

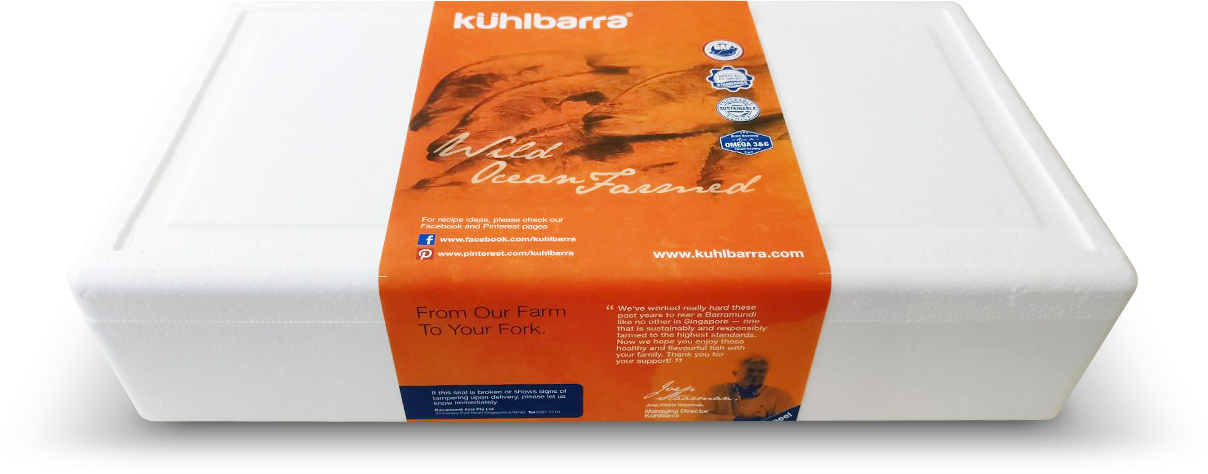

Processing Facility: Perfectly packaged

We clean and slice our fish in a cold room after harvesting. Then, the firm thick fillets, carefully vacuum-packed, go into insulated, ice-filled boxes.

Ah Heng

Processing Supervisor

“Our fish are carefully scaled, portioned, and deboned before individually vacuum-packing each piece and packing them in boxes filled with fresh ice to preserve their freshness and flavour! They’re ready to cook when they reach consumers.”

Both our processing system and cold chain have even received the International Organisation for Standardisation certification!

Bruno Gillet

Processing Manager

“Our ISO-certification is testament to the high standards of processing we uphold and take pride in. We’ve said this before but we’ll say it again – there’s no room for compromise on freshness, safety and flavour.”

Scroll to Continue

04

Delivery: Hey ho, let’s go!

Direct from the farm to your home. That's probably us at your door right now!

Themis Lin,

Sales Manager

“If you’ve any enquires or feedback, just drop us a call and I’ll be delighted to chat with you! Happy customers make everything we do all worth the while.”

Did you know?

Kühlbarra barramundi aren’t just supplied to you and acclaimed hotels and restaurants in Singapore, they are also exported weekly to Australia, Hong Kong and the United States! The SFA drops by our processing facility weekly to make sure our impeccably fresh fish meets the stringent international standards for food export.

Eva Lim

Director, Global Sales & Marketing

“Our vision for our locally-grown barramundi is for it to spread its fins even wider and conquer more parts of the globe, armed with the unwavering support of our customers!”

We like to share – and this is our way of sharing Singapore with the rest of the world, one barramundi at a time.

Happy eating and stay Kühl!

Happy eating and stay Kühl!